The Indian automobile manufacturing sector has long thrived on scale and cost-competitiveness. However, over the last decade, and especially in recent years, the market has shifted its focus toward smarter, leaner, and more sophisticated production systems. The adoption of advanced manufacturing techniques, robotics, automation, AI-driven quality checks, and digital twins has changed the landscape. Not only are these technologies enhancing output and quality, but they are also critical to meeting India’s aspirations of being a global automotive manufacturing powerhouse.

The Rise of Automation and Robotics

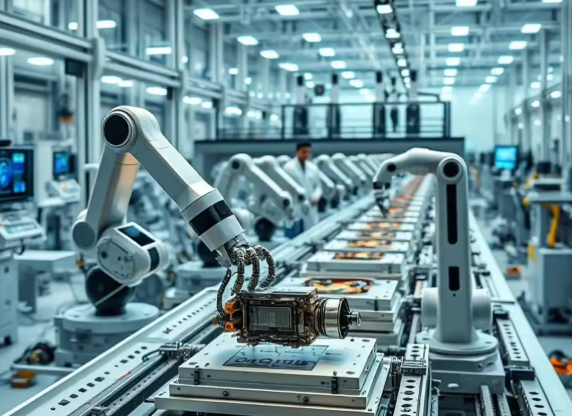

Automation refers to the use of technology (both hardware and software) to perform tasks that humans previously managed, ranging from simple repetitive tasks to more complex decision-making processes. Robotics forms a subcategory, focused on programmable machines capable of executing assembly, welding, painting, material handling, and inspection with high accuracy.

In Indian automotive factories, robots now populate shop floors, welding car bodies, painting with precision, and assembling components at breakneck speed. According to a report by the International Federation of Robotics, robotics adoption in India’s manufacturing industry is projected to grow by 20% annually in the coming years, a pace that reflects global trends and rising domestic demand for high-grade vehicles.

The benefits have been significant:

- Productivity Gains: Robots and automated assembly lines work longer hours without fatigue, drastically increasing throughput and reducing downtime.

- Quality Consistency: Automation minimizes human error, critical for strict tolerance levels required in automotive engineering.

- Cost Efficiency: Although the initial investment is high, the long-term savings are substantial because of reduced labor costs and wastage.

Industry 4.0: Smart Factories and the Digital Revolution

Industry 4.0 encompasses the latest wave of technological change, characterized by the fusion of cyber-physical systems, Internet of Things (IoT), big data, artificial intelligence, and cloud computing within the manufacturing process. Smart factories leverage these innovations for real-time data exchange, predictive maintenance, and adaptive manufacturing.

Key Industry 4.0 pillars in Indian automotive plants include:

- Industrial Internet of Things (IIoT): Networked sensors and machines provide real-time data on equipment health, inventory status, and workflow bottlenecks, allowing for rapid problem-solving and resource optimization.

- Advanced Control Systems: Platforms such as Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA), and Programmable Logic Controllers (PLC) ensure precise and reliable operation of equipment.

- Human-Machine Interfaces (HMI): User-friendly interfaces empower plant operators to monitor and control processes seamlessly.

3D Printing: Shaping the Next Generation of Automobile Manufacturing

Although still in its early phase, 3D printing (additive manufacturing) is creating ripples in Indian automotive plants. It allows for rapid prototyping, reduces lead time in design-testing cycles, and enables the creation of complex components that are difficult or impossible to produce with conventional methods.

Benefits include:

- Rapid Tooling and Prototyping: Significantly shorter development cycles for new models and variants, giving manufacturers a competitive edge.

- Customization: Ability to produce bespoke components for individual requirements at scale.

- Waste Reduction: Material usage is highly efficient, supporting broader sustainability goals.

Workforce Development: The Human Factor in Advanced Manufacturing

While automation and Industry 4.0 are hardware- and software-intensive, their success relies on people. Skilled operators, programmers, and maintenance technicians are crucial for running, troubleshooting, and improving these advanced systems.

India faces a unique challenge: despite having a large labor pool, there is a shortage of workers skilled in advanced automation, robotics programming, and digital technologies. To address this gap, industry-academia collaborations are ramping up. For example, Ashok Leyland has partnered with IIT Madras to run targeted workforce development programs, dramatically improving competencies in operating advanced manufacturing systems.

According to a recent study, 70% of efforts in closing the skills gap are directed toward training programs, while another 30% focus on fostering partnerships between academia and industry. Comparative analysis suggests that while China reports 70% workforce proficiency in advanced manufacturing, India currently stands at 50%, highlighting the urgent need for upskilling efforts.